Crane ropes are essential for lifting and hoisting heavy objects and are designed for durability, strength, and performance. Choosing the ideal crane rope requires understanding the various types, materials, and construction methods available in the market. Here is a detailed guide to help you make an informed decision.

Crane rope composition

The crane rope is made up of three essential elements that work together to ensure its performance. At the core, individual metal wires are twisted into a single strand. These strands are then wound around a central core, which can either be made of steel or fiber. The multi-strand structure provides the rope with strength, flexibility, and long-lasting durability. The core adds stability and support to the rope, enabling it to withstand the intense loads and stress of lifting operations. Together, these components make the crane rope reliable and efficient for heavy-duty tasks.

Factors to consider when choosing crane ropes

1. Rope material selection

The material of the rope determines its applicability and performance in a specific working environment. There are two main types of materials to choose from: wire rope and synthetic fiber rope.

A. Wire rope:

With its high strength, wear resistance, and tensile strength, it performs well in heavy lifting and harsh environments. Wire crane rope is very suitable for applications that require high tension or extreme temperatures, and is usually suitable for high-load and large-tonnage operations.

Composition of wire rope:

Wire rope is a rope made of multiple single steel wires twisted together. The structure of wire rope is usually divided into:

•Strand: A “strand” made of multiple thin steel wires twisted together.

•Rope: A complete wire crane rope is formed by twisting multiple “strands” together.

•Structural features of wire rope:

•Single-strand steel wire: Usually made of high-strength steel with excellent tensile strength.

•Multi-strand structure: Generally speaking, wire rope contains multiple strands, each of which is composed of several thin steel wires, which are twisted together to form a relatively strong and durable rope body.

Advantages of wire rope:

•High strength: Due to the structure of multiple strands of steel wire, wire rope can withstand greater tension.

•Strong durability: Suitable for high-load operations, especially in equipment such as cranes and tower cranes, and can withstand long-term use and wear.

•Wide adaptability: Wire ideal crane rope is not only suitable for ordinary industrial lifting, but also can be used in harsh environments such as offshore operations and mines.

B. Synthetic fiber crane rope:

Synthetic fiber rope in crane rope is an increasingly common alternative to wire crane rope in modern lifting machinery, especially in applications that require high strength, low weight, and corrosion resistance. The use of synthetic fiber rope in the crane industry usually involves some special requirements, such as heavy load lifting, high-frequency operation, and high safety standards.

Advantages of synthetic fiber crane rope:

• Lightweight:

Synthetic fiber ropes are much lighter than steel wire ropes, which can significantly reduce the burden on cranes, especially when high-rise or large-tonnage objects need to be lifted. Reducing the weight of the rope can improve efficiency and reduce mechanical wear.

•High strength:

Some synthetic fiber ropes (such as polyethylene, nylon, etc.) have very high tensile strength and can provide sufficient safety guarantees under high loads. In particular, ultra-high molecular weight polyethylene ropes (UHMWPE) have a tensile strength comparable to or greater than that of steel wire ropes.

•Strong corrosion resistance:

Synthetic fiber ropes show corrosion resistance that steel wire ideal crane ropes cannot match in wet or corrosive environments such as oceans and chemical plants. They will not rust like steel wire ropes and have a longer service life.

•Flexibility and easy operation:

Synthetic fiber ideal crane ropes are very soft and easy to bypass the sheave or pass through the pulley system of the crane during operation, reducing rope wear and relatively less susceptible to friction damage. Compared with steel wire ropes, they are generally less likely to cause damage or scratches.

•UV resistance:

Synthetic fiber ropes, especially polyester (such as Dacron) and polypropylene, have good UV resistance and can adapt to working environments exposed to sunlight for a long time.

•High safety:

Since synthetic fiber crane ropes do not bend or deform significantly before breaking like steel wire ropes, their breaks are usually smoother and less prone to sudden breaks, increasing safety during operation.

Common types of synthetic fiber crane ropes:

•Polyester Rope:

Polyester fiber ideal crane rope has strong UV resistance, corrosion resistance, and is not easily absorbed by water in humid environments. It is usually used for lifting operations with medium loads.

•Nylon Rope:

Nylon rope has excellent tensile strength and elasticity, but it has strong water absorption and may lose strength in humid environments. In crane applications, it is usually suitable for work that requires high impact or tensile forces.

•Polyethylene Rope:

Polyethylene (such as UHMWPE) is one of the strongest synthetic fibers currently available, with extremely high tensile strength and very light. It is stronger and lighter than steel wire rope, suitable for operations with extremely high weight and strength requirements, such as heavy lifting.

•Polypropylene Rope:

Polypropylene crane rope is light and buoyant, but has low tensile strength and is usually used for lighter lifting tasks, especially in water operations.

Notes on synthetic fiber crane ropes:

Strength limit:

Although the strength of synthetic fiber crane ropes is already very high, steel wire ropes are still a stronger choice in extremely high-load working environments. When designing a lifting system, you must ensure that the synthetic fiber rope can meet the requirements of the workload.

•Heat resistance:

Synthetic fiber ropes have relatively poor heat resistance and usually lose strength in high-temperature environments. Therefore, in high-temperature working environments, you need to be careful to choose the right rope material.

•Care and maintenance:

Synthetic fiber ropes need to be checked regularly to ensure that there is no wear, tear, or other damage, especially in extreme working environments. Although they are more corrosion-resistant than steel wire ropes, they still need regular cleaning and maintenance.

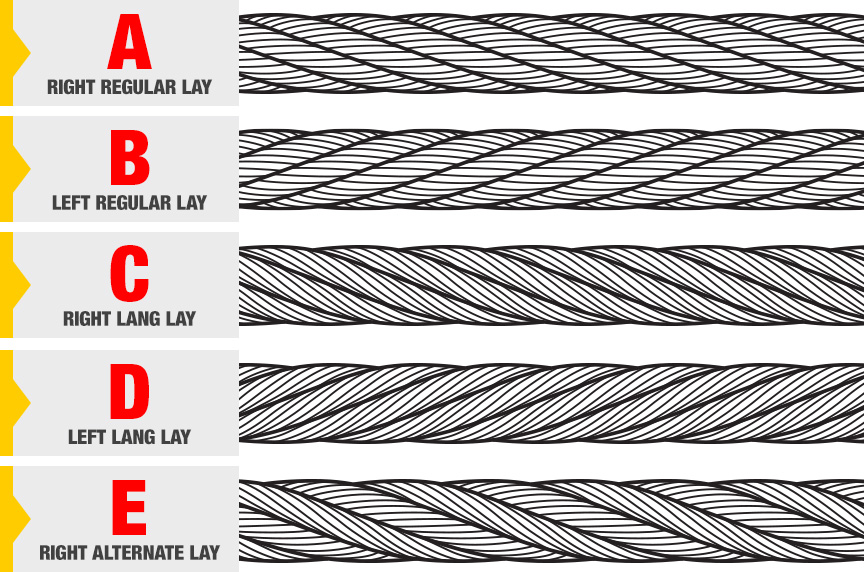

2. Type of Lay and Direction

Regular Lay

In a regular lay configuration, the individual wires of the rope run along its axis, while the strands are laid in the opposite direction to the wire lay within each strand. Regular lay ropes are known for their resistance to crushing, reduced rotation, and efficient spooling onto drums, especially when compared to lang lay ropes.

Lang Lay

Lang lay ropes feature wires that are angled relative to the axis of the rope. In this configuration, both the wire lay and the strand lay are oriented in the same direction. Lang lay ropes are highly resistant to fatigue and wear, offering superior abrasion resistance.

Alternate Lay

Alternate lay ropes combine strands with alternating regular lay and long lay configurations. This type of rope is typically used in specialized applications where distinct performance characteristics, such as specific fatigue or wear resistance, are required.

3. Crane Rope carrying capacity

When selecting an ideal crane rope, you must ensure that its maximum carrying capacity exceeds the rated load of the crane. The load-bearing capacity of a crane rope usually depends on its material, diameter, structure, and design. A rope with too low a load-bearing capacity may cause breakage or fatigue damage, thus affecting safety.

Rated load: Each ideal crane rope has its rated upper limit of tension. When selecting, it should be based on the operating requirements of the crane to ensure that the rope’s tension capacity is 1.5 to 2 times higher than the maximum working load (safety factor).

4. Structural design of the crane rope

The structure of the ideal crane rope directly affects its tensile strength, wear resistance, torsion resistance, and service life. Common structural designs are as follows:

•Six-strand rope: A standard structure consisting of six steel wires, suitable for general medium-load operations, with both strength and flexibility.

•Eight-strand rope: This structure is stronger than the six-strand rope and is suitable for lifting scenarios requiring higher load capacity or frequent operations, and is usually used in heavy cranes.

•Rotation-resistant rope: Specially designed to reduce the twisting of the ideal crane rope due to rotation during lifting operations. This type of ideal crane rope is suitable for high-frequency, high-load work and can effectively prevent the rope from being entangled or damaged.

5. Environmental adaptability

Environmental conditions have a significant impact on the durability and safety of the rope. Considering environmental factors can effectively extend the service life of crane ropes.

•Humidity and corrosion: In offshore operations or chemical environments, highly corrosive air or liquids will accelerate the aging of ropes. Steel wire crane ropes can be improved by anti-corrosion treatments such as galvanizing and chrome plating to improve corrosion resistance, while synthetic fiber ropes are sensitive to humidity and need to be checked regularly to prevent mold or structural damage.

•Temperature: When the temperature changes greatly, steel wire ropes usually perform better and can maintain high strength at high temperatures. Synthetic fiber ideal crane ropes are more affected by high temperatures, and excessively high temperatures may cause their strength to decrease.

•Ultraviolet rays: Synthetic fiber crane ropes are particularly susceptible to ultraviolet rays, and long-term exposure to sunlight may cause them to become brittle or age. Therefore, the influence of ultraviolet rays should be considered when working outdoors.

6. Working frequency and load fluctuations

Under different working conditions, the load fluctuations and operating frequencies of ideal crane ropes vary. Frequent lifting and lowering operations will accelerate the wear of ropes.

•High-load operations: For large-load operations, it is recommended to choose high-strength steel wire ropes, whose fatigue resistance and tensile resistance can meet the needs of heavy machinery.

•Light load or high-frequency operation: Synthetic fiber ropes are suitable for frequent and fast operations due to their light weight and strong flexibility, but their load-bearing capacity is not as good as that of wire ropes.

7. Rope maintenance and inspection requirements

Different types of ideal crane ropes require different levels of maintenance and inspection. Regular inspections can detect potential problems in time and avoid accidents.

•Wire ropes: It is necessary to regularly check whether the wires are broken, worn, corroded, twisted or deformed. Wire rope maintenance includes regular lubrication and cleaning to reduce wear.

•Synthetic fiber ropes: They are sensitive to factors such as ambient temperature and ultraviolet rays. They usually need to avoid long-term exposure to harsh environments and regularly check for wear and tear. The maintenance requirements are relatively low, but attention should still be paid to damage to the rope surface.

8. Service life and economy

The service life of the ideal crane rope directly affects the maintenance cost and replacement frequency. Wire ropes are usually able to maintain stable operation for a long time due to their high wear resistance and strength. Synthetic fiber ropes are relatively prone to wear, especially under high loads or long-term exposure to harsh environments.

•Wire rope: Under extreme conditions, it has a long overall lifespan, although it requires regular inspection and maintenance.

•Synthetic fiber rope: Although the initial cost is higher, in some low-load, non-heavy-duty operations, its light weight and ease of installation may reduce overall operating costs.

Summary

When choosing the ideal crane rope, it is necessary to comprehensively consider the rope’s material, structure, load-bearing capacity, environmental adaptability, frequency of use, maintenance requirements, and economy. Reasonable selection of the ideal crane rope can not only improve the crane’s operating efficiency but also maximize the safety of the operation and extend the service life of the equipment. Through these careful considerations, it can be ensured that the most appropriate rope type is selected in different operating environments to meet work needs and ensure safety.

The crawler crane undercarriage is an important part of a crawler crane. How to choose high-quality undercarriage for crawler crane? The best crawler crane undercarriage supplier is here! Contact Us!!!