Choosing a reliable large-tonnage crane track shoe manufacturer is essential to ensure the safety of the project while ensuring the long-term use of the crawler track shoe. As a specialist manufacturer of crawler crane undercarriage parts, we understand the importance of providing customized solutions that meet our customers’ unique needs. With our rich production experience and understanding of undercarriage parts, we are very professional in customizing 300-ton crane track shoes.

Shandong VM is proud to be the leading manufacturer and developer of high-quality undercarriage parts for crawler cranes. Drawing on our expertise in designing and manufacturing track shoes, we offer an unparalleled customization service for crawler cranes with capacities up to 300 tonnes. Let us guide you through the steps of customizing crawler crane track shoes and demonstrate our commitment to delivering exceptional results.

Step 1: Understanding Your Requirements

The first and most crucial step in our customization process is gaining a comprehensive understanding of your specific needs. We encourage open communication to gather critical details such as crawler crane models, tonnage, and operating conditions. By understanding these requirements, we can ensure that the crane track shoes we create are perfectly tailored to your crawler crane.

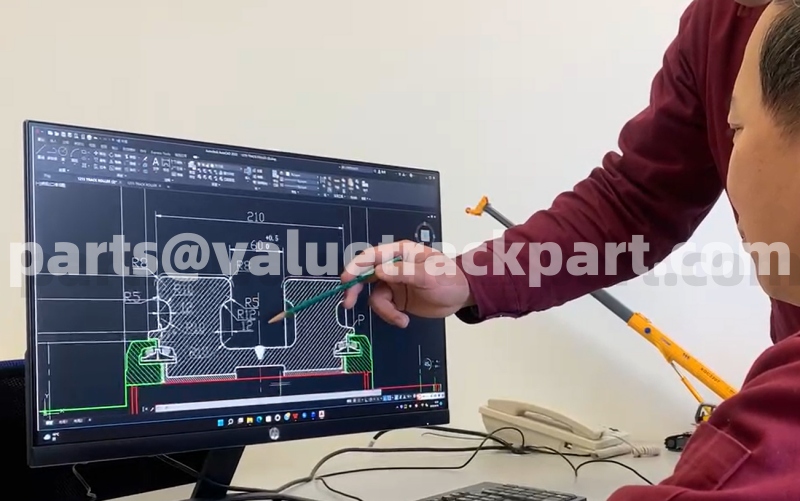

Step 2: Make drawings and determine technical requirements

Based on the information provided by the customer, our team of engineers will use their experience in the crawler crane industry to design crane track shoe drawings that accurately match your specifications. The crawler track pads are then modeled using advanced technology and cutting-edge software to ensure optimal performance and long-lasting durability.

Step 3: Strict quality assurance

The quality control of crane track shoes is our top priority in customizing crawler track parts for customers. After the design phase is completed, we will conduct strict quality inspections on the track plates to ensure compliance with the standard technical requirements of a 300-ton crawler crane undercarriage. Our professional quality control team conducts thorough inspections to ensure that every crawler crane track shoe you receive meets international standards.

Step 4: Customization and manufacturing

After the Crawler crane track shoes pass strict quality inspection, we enter the customization and manufacturing process. Our skilled technicians utilize state-of-the-art machinery and follow industry best practices to manufacture crane track pads with high precision and precise attention to detail. We use high-quality materials and advanced production processes to ensure optimal performance and extended service life of the crawler crane parts.

Step 5: Testing and Validation

We conduct a meticulous testing and verification process before shipping the track pads to your designated location. Our comprehensive inspection covers factors such as load-bearing capacity, wear resistance and dimensional accuracy, ensuring the crane track shoe is fully capable of meeting the demands of the most challenging crane operations.

Step 6: Quick Delivery and Customer Satisfaction

Based on our stable production capacity and transportation capacity, we are able to guarantee timely and hassle-free delivery to any destination. Whether you need to ship from Qingdao, Dalian, or Shanghai port, we will meet your needs and provide flexible shipping options based on your needs. Our experience in managing transportation logistics and commitment to customer satisfaction ensure a quick and reliable delivery process.

Choose us as your trusted partner for customizing 300-ton crane track shoes and experience the unparalleled precision and quality of track shoes. We are committed to producing high-quality crawler undercarriage parts, ensuring that we serve every customer wholeheartedly and provide customers with the best solutions. Contact us today and let us exceed your expectations with exceptional custom service and track shoes to enhance the performance of your crane.

The track pad of our commonly seen 300-ton crawler cranes includes Liebherr LR1300 Track pad, Liebherr LR1280 Crawler Crane track shoe, Manitowoc 2250 track pad, Link-Belt LS348 track shoe, Manitowoc MLC300 track pad, Lima 7700 track shoe, Sany SCC3000 track shoe, XCMG QUY300 track shoe and so on.

Contact Us:

Telephone: +86 535 671 0636

Whatsapp:+86 15253585909

Mail: Parts@valuetrackpart.com

Website: www.valuetrackpart.com