Advantages of forging with NIPPON SHARYO DH550-5 Bottom Roller

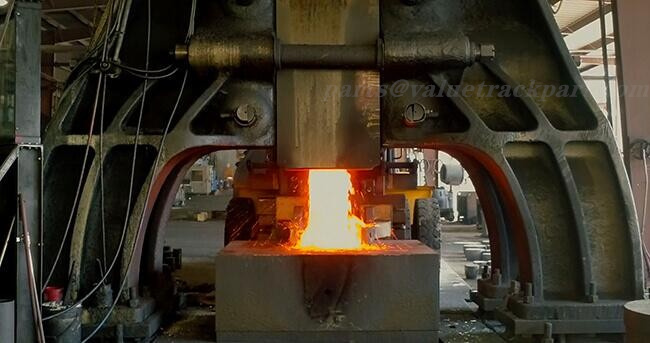

Forging is a processing method that uses forging machinery to apply pressure to metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. It is one of the two major components of forging (forging and stamping). Forging can eliminate defects such as as-cast porosity produced in the metal smelting process and optimize the microstructure. At the same time, due to the preservation of complete metal flow lines, the mechanical properties of forgings are generally better than castings of the same material.

Compared with castings, metal can improve its structure and mechanical properties after forging. Due to the deformation and recrystallization of the metal after the casting structure is thermally processed and deformed by forging, the original coarse dendrites and columnar grains become an equiaxed recrystallization structure with finer grains and uniform size, so that the original segregation, The compaction and welding of porosity, pores, slag inclusions, etc. will make the structure more compact and improve the plasticity and mechanical properties of the metal.

During the heat treatment of the crawler crane roller, place the test block in the center of the furnace or at a balanced position in the furnace to avoid being affected by the flow of hot air. After the heat treatment is completed, the sample is taken out and subjected to metallographic structure analysis, hardness test and other related tests to understand the effect of the heat treatment process.

The mechanical properties of castings are lower than those of forgings of the same material. In addition, the forging process can ensure the continuity of the metal fiber structure, so that the fiber structure of the forging is consistent with the shape of the forging, and the metal streamline is complete, which can ensure that the parts have good mechanical properties and long service life.

A forging is an object in which a metal is pressured to form a required shape or a suitable compression force through plastic deformation. This force is typically achieved through the use of a hammer or pressure. The forging process creates a refined grain structure and improves the physical properties of the metal. In the actual use of components, a correct design can make the particle flow in the direction of the main pressure. It can make the service life of forgings longer.

So our NIPPON SHARYO DH550-5 Bottom Roller has better plasticity and mechanical properties than ordinary bottom rollers, and has a longer service life.

We manufacture and sell track shoes, bottom rollers, top rollers, sprocket, and Idler for NIPPON SHARYO D308 D408 D508 DH300-3 DH308 DH350 DH400 DH400 III DH408 DH500 DH500-5 DH508 DH508-105M DH550-3 DH550-5 DH558 DH600 DH608 DH608-120MDH650 DH650-5 DH658 DH700 DH758 DH800 DHJ40 DHJ60 DHP70 DHP80 DP100 ED4000 ED5000 ED5500 ED5800H DH900

If necessary, please contact:

Telephone: +86 535 671 0636

Whatsapp/WeChat:+86 15253585909

Mail: Parts@valuetrackpart.com

Website: www.valuetrackpart.com