Nippon Sharyo DH400 crane crawler shoes adopt advanced casting and heat treatment technology and meet ISO 9001 certification standards. If you need crane track shoe of DH308, DH350, DH400, DH400-III, DH408, DH500, DH500-5, DH508, and other models, please contact us

Nippon Sharyo DH400 Crane Track Shoe Information

Packaging Details: Export Standard Pallet / Plywood Case

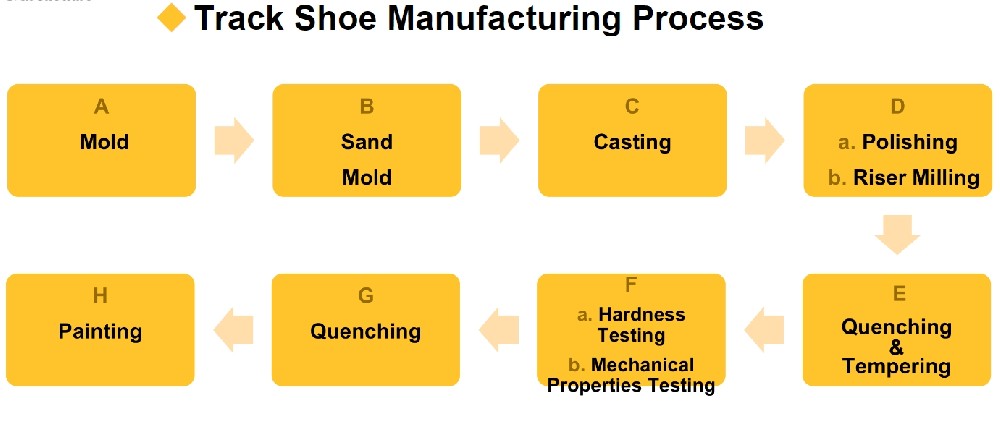

Manufacturing Process: Casting

Heat Treatment: Whole Quenching and Tempering, followed by Surface Hardening

Brand Name: VM®

Payment Terms: T/T, L/C

Certification: ISO 9001

Nippon Sharyo DH400 Crane Track Shoe Production Process

Professional Nippon Sharyo DH400 Crane Track Shoe Manufacturer

•Efficient production lines and large-scale production capacity

Our factory is equipped with multiple modern production lines and can produce a large number of Nippon Sharyo DH400 crane track plates annually, which can meet the needs of large-volume orders, ensure on-time delivery, and maintain high production efficiency.

•Strong mold manufacturing capabilities

The factory has a dedicated mold-making department that can quickly design and produce customized molds according to different Nippon Sharyo DH400 track pad models and specifications to ensure flexibility and precision in the production process.

•Advanced casting and heat treatment technology

The factory uses advanced casting equipment and fully automated heat treatment systems to ensure that the hardness and strength of the Nippon Sharyo DH400 crane track shoes are in the best state, ensuring the high-quality standards of each batch of Nippon Sharyo DH400 crane track shoes.

Other Nippon Sharyo Crane Undercarriage Parts

DH308, DH350, DH400, DH400-III, DH408, DH500, DH500-5, DH508, DH508-105M, DH550-3, DH550-5, DH558, DH600, DH608, DH608-120M, DH650, DH650-5, DH658,DH700, DH758, DH718, DH900, DH758-160M, DH900-2(DH900-5), DHJ30, DHJ40, DHJ60, DHP70, DHP80, DHP100, ED4000, ED5000, ED5500, ED5800H…