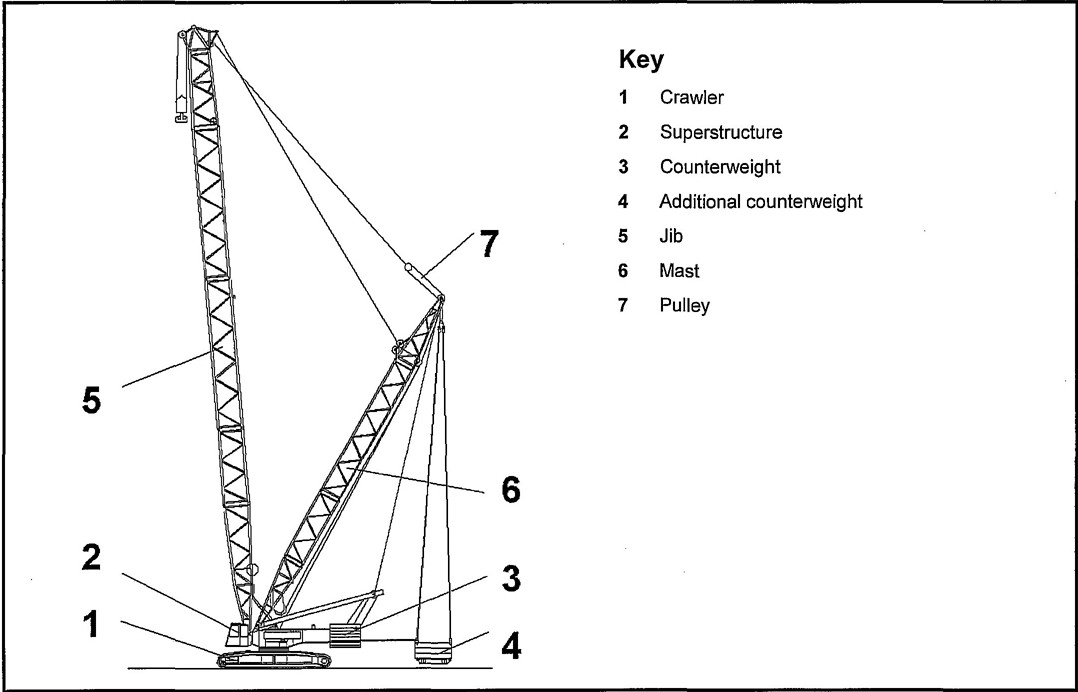

Crawler cranes are essential heavy lifting machinery used in construction, mining, and large industrial projects. This article explores the different crawler crane pulley type, their functions, and how they impact the performance of these lifting equipment machines.

Role of Pulleys in Crawler Cranes

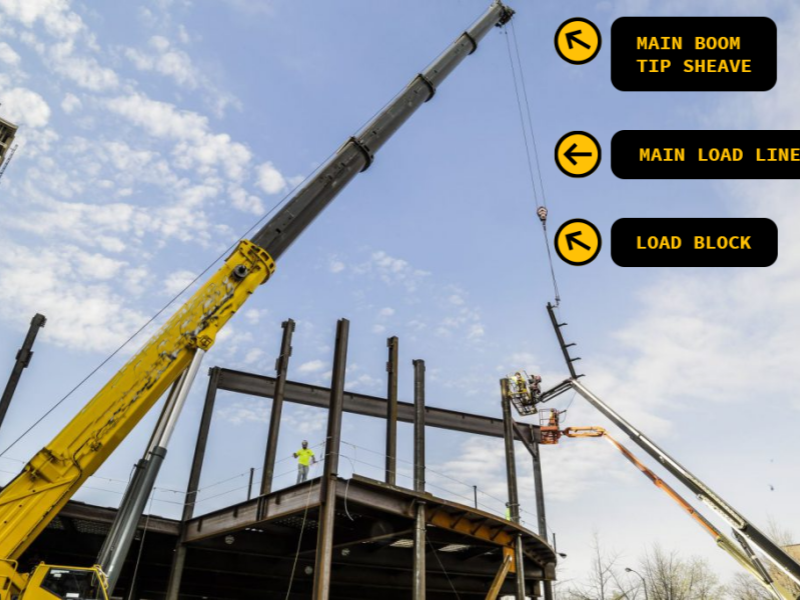

Pulleys are lifting equipment components used to change the direction of a hoisting rope or cable, which is essential for transmitting the lifting force. In crawler cranes, pulleys are designed to withstand the enormous weight and pressure generated during the lifting process. These pulleys are an integral part of the crane’s hoisting system, which typically includes a hoist drum, ropes, and a block and tackle assembly that make up a pulley block or system.

By reducing the amount of effort required to lift, crawler crane pulleys make it easier for cranes to handle large weights. In addition, they help control the movement and positioning of loads, ensuring precision and safety during operations.

Types of Crawler Crane Pulleys

Crawler crane pulleys are designed in different configurations depending on the type of crane, the expected load, and the specific task to be performed. Below, we will focus on the three main types of crawler crane pulleys commonly used in the lifting equipment industry:

1. Fixed Crawler Crane Pulley

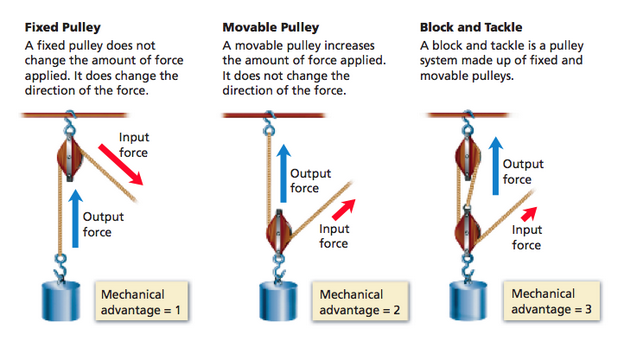

The fixed pulley is one of the most commonly used types in crawler cranes. As the name implies, the fixed pulley is firmly mounted and does not move along the structure of the crane. Its main function is to change the direction of the lifting rope, making it easier for the operator to lift the load vertically.

rope, making it easier for the operator to lift the load vertically.

Fixed crawler crane pulleys are often used in conjunction with other crawler crane pulley to increase the lifting capacity of the crane. Although fixed pulleys do not directly reduce the lifting load, they can provide the necessary mechanical advantage when used in conjunction with a movable pulley or pulley system.

Main Features:

Simple structure and easy maintenance

Mainly changes the direction of the lifting rope

Provides a mechanical advantage when used in a movable pulley system

2. Movable Pulley

As the name implies, the movable pulley can move along the structure of the crane, providing a mechanical advantage by reducing the force required to lift the load. The movable pulley itself does not change the direction of the lifting rope, but works in conjunction with other fixed pulleys to increase the overall lifting capacity.

In most crawler crane systems, the movable pulley is part of a pulley block system where the cable is wrapped around multiple pulleys. By using multiple movable pulleys, the system can lift heavier loads with less force, which is a significant advantage in heavy lifting operations.

Main Features:

Reduces the force required to lift heavy objects

Often used in pulley blocks with multiple crawler crane pulleys

Increases lifting equipment capacity and efficiency

3. Crawler Crane Pulley Block System

A pulley block is a collection of multiple pulleys (fixed and movable) that are housed in a unit. A pulley block is a more complex system than a single pulley that provides greater lifting efficiency. By combining multiple pulleys, a pulley block can increase the mechanical advantage, allowing crawler cranes to lift extremely heavy loads with relatively low force.

Pulley block systems are often used in crawler cranes for large construction projects, such as the construction of skyscrapers, bridges, or offshore platforms. The ability to distribute the lifting load over multiple crawler crane pulleys increases the crane’s lifting capacity while improving safety and control during operation.

Key Features:

Multiple pulleys (fixed and movable) within a single block

Mechanical advantage for lifting heavy objects

Commonly used in large construction and lifting tasks